Satellite Roller Screws

Satellite Roller Screws

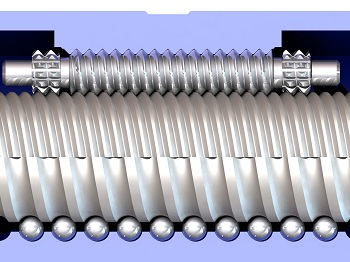

The Rigid design of a Satellite Roller Screw also known as Planetary Roller Screws give them the ability to deliver very heavy load capacity due to the many contact points between the rollers and screw. Satellite roller screws can be up to 90% efficient and have an expected life up to 15 times longer than any ball screw equivalent. They allow for high acceleration and deceleration and in some designs could even exceed 5000 rpm, making the roller screw product a superior linear drive alternative.

- The bearing elements are threaded rollers between the screw and nut.

- The high number of points of contact enables satellite roller screws to support heavy loads.

- The range can include revers roller screws and the differential type screw.

- Sizes from 3.5mm to 210mm in diameter with from 1mm lead to 50mm.

- Left and right-hand available.

- Steel and stainless steel.

Satellite Roller Screws are like a ball screw but the main difference is that the load transfer elements are threaded rollers and not balls, this allows for a high number of points of contact to support the load.

Load capacity and lifespan

The Main advantage of roller screws compare to ball screws is that their admissible static and dynamic load capacities are higher. The bearing function is ensured by threaded rollers instead of balls and the load is spread over a higher number of points of contact.

Hertz's Law

The admissible Hertz pressure is the same for satellite roller screws and ball screws. Satellite roller screws thus have a static load 3 times greater than that of ball screws and their lifespan is 15 time longer.

Speed & acceleration

Satellite roller screws can rotate much faster and support much greater acceleration than ball screws, the RV satellite roller screws are designed so that the rollers are not recycled. This means the mechanism can support twice the rotation speed of a ball screw and acceleration can reach up to 3g.

Lead & Pitch

Planetary roller screw can be achieved with smaller leads compared to ball screws.

As the lead is a function of the pitch of the planetary roller screw, the lead can be very small (0.5mm and even less). Planetary roller screws can be achieved with entire or real numbers(i.e. lead of 3.32mm per revolution), which avoid reduction gears. This is an advantage compared to ball screws. The lead can be chosen and realised without any geometrical changes of both the screw shaft and the nut body, which allows updates with minor changes.

A ball screw the lead is limited by the dimension (OD) of the bearing ball, which is a standard feature.

Rigidity & strength

The many points of contact give satellite roller screws greater rigidity and shock tolerance than a ball screw.

Please contact us with your requirements